Racing Sails

Race winning sails without the name brand mark-up.

Island Planet Sails founder Dave Benjamin began working at a sail loft in the mid-90’s because of his appetite for racing. Now he enjoys shipping winning racing sails to sailors around the world.

Island Planet Sails separates industry hype from reality on a daily basis. We spend time with you, asking questions and discussing your specific racing needs. Whether you’re beer can racing or competing at a professional level, we can provide a winning sail for your next race that doesn’t break the bank.

Why Island Planet?

Island Planet has a rather unique approach when it comes to racing sails. We don’t have commissioned salesmen pushing you into spending more than you need to or overdoing the inventory. We take a holistic approach and don’t be surprised if some of our suggestions have nothing to do with sails. For instance, we had a prospective client come to us asking about a carbon genoa for his 40′ Hunter with shoal draft keel and furling main that he primarily uses for club racing. One of our first questions was whether or not he had a feathering or folding prop. Our goal is to help you win races and have fun. We’re willing to look beyond our own interests to do that. We want to be your sailmaker for the long term.

The Island Planet Difference

Material Choices

Crosscut and radial wovens

Economical performance

Today’s woven sailcloth is more stable and stretch resistant than in the past. Dimension Polyant and Challenge manufacture cloth designed for radial construction. Racers who prefer the easy handling and durability of woven cloth can choose a great performing radial Dacron or even a cloth that incorporates high tech fibers.

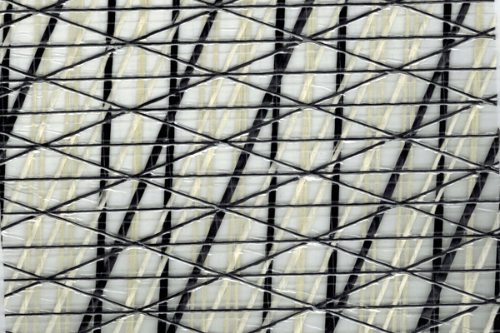

Conventional sewn laminates

Traditional way to win

Racing laminates have long been favored by racing sailors. They are more stretch resistant than wovens and reinforced with a variety of fibers. Modern laminates outlast prior versions and are less susceptible to mildew. Radial sails can be constructed with lighter weight cloth in the more lightly loaded areas to achieve additional weight savings.

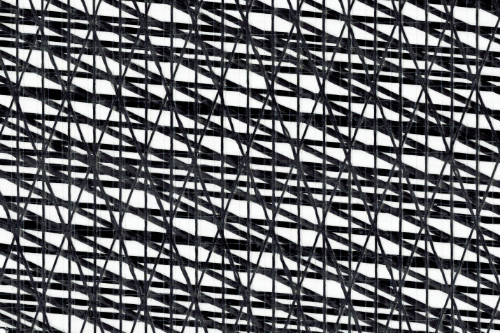

Load Path technology

Best strength to weight

Load Path technology represents a quantum leap in sail manufacturing. It starts with a crosscut panel layout using a variety of different base materials. Highly sophisticated “stringing machines” place reinforcing fibers precisely on the load paths of the sail. This is the most efficient construction technique in the history of sailmaking.