Cruising Sails

Cruising sails for the real world.

Island Planet Sails is owned and staffed by cruisers, so our passion for cruising is no surprise. We know cruising means different things to different sailors. For some, it may mean participating in a major rally. Other sailors simply enjoy gunkholing in Chesapeake Bay. Whatever cruising means to you, we can enhance your cruising with well designed bulletproof cruising sails.

Why Island Planet?

Whichever sailmaker you choose for the critical investment for your cruising boat, it goes without saying, they should be passionate about cruising sails. Many lofts, particularly the big brand names, tend to be “race-centric”. How many times have you heard about a cruiser trying to get a repair done at a loft getting told, “sorry, we had sails that needed to be done by this weekend’s regatta”. We take the time needed to get to know you, your boat, and your cruising plans. Then we design and build sails that go the distance with minimal maintenance requirements.

The Island Planet difference

Material Choices

Crosscut and radial wovens

Reliability and ease

Modern woven sailcloth has much to offer. These days, Dacron is more stable and stretch resistant than it ever has been. Dimension Polyant and Challenge offer cloth specifically developed for radial construction. Performance cruisers and racers who want an added edge while retaining the economy and durability of Dacron can invest in a radial sail or a woven that incorporates Dyneema.

Classic sewn laminates

Proven performance

Cruising laminates are a mature well understood offering. They allow us to provide you with a sail that is more stretch resistant than a sail manufactured from a woven cloth that weighs a bit less. Modern laminates last longer than the old ones and are less susceptible to mildew. Radial laminates can b constructed with lighter weight cloth in the more lightly loaded areas to achieve some weight savings.

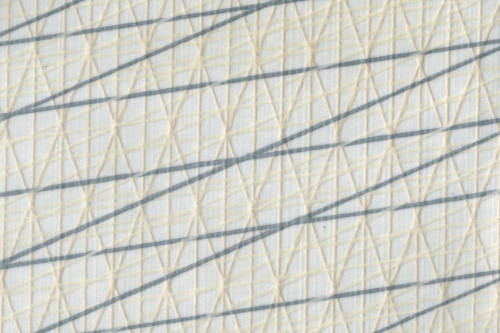

Load Path technology

Strongest and lightest

Load Path technology is quickly eclipsing more traditional manufacturing methods. It starts with a crosscut panel layout using a variety of different base materials. Highly sophisticated “stringing machines”

place reinforcing fibers precisely on the load paths of the sail. This is the most efficient construction technique in the history of sailmaking. With taffetas, it’s ideal for cruising applications.